At ITMA Mazziniici e Alena Nw, of Aeris Group Holding, present the innovative integrated system for air filtration and humidification VERSA IHS for textile manufacturing departments and non-woven

Aeris Group is a holding, based in Italy, controlling corporate companies operating for years in the air treatment field for production processes and departments, from heating to ventilation and conditioning up to filtration.

The Group will be present at ITMA with two of its brands: Mazziniici and Alena NW.

Mazziniici is a historic brand that deals with aeraulic solutions exclusively for the Textile field; Alena NW, last born of the Group, follows the non-woven field.

Part of the holding are also Aeris Technologies, an Engineering, Procurement & Construction company (EPC) for the HVAC and antipollution, and Edenya, active in evaporative cooling for industrial environments.

All the companies of the Group work in according to ISO 9001: 2015 quality certification.

«It is the synergy of the Group that makes the difference – explains Eros Nani, CEO of Aeris Group Holding – in a continuous sharing of experiences between the companies, each unique for its own specificity but all with the same background».

«This benefits our growth» continues Nani. «The different fields of application allow us to develop new systems and to approach solutions that can be proposed by our corporates in different industrial application. The common purpose is to obtain the best efficiency for each solution, minimizing investment and management costs as much as possible and, for sure, minimizing the payback of our customer’s investment».

A certified solution granting reduction of energy and water consumption

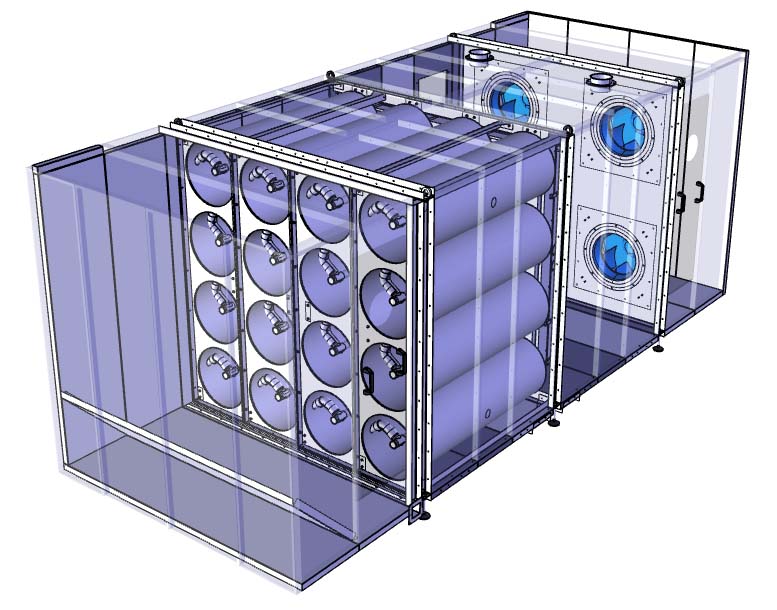

The concrete example of this purpose’s realization, for the Textile and non-woven field, will be exhibited at ITMA 2019 in Barcelona. It is an integrated system, Versadrums filtration unit and IHS cooling/humidification section. The system was awarded by the European Community within the Horizon 2020 project, European framework program for research and innovation born in 2017 to support the best entrepreneurs and scientists in the market launch of their innovative ideas.

This award was given after the achievement of the “Seal of Excellence”, following a highly competitive assessment. The IHS project has been evaluated by the European Commission as a proposal of high quality and innovation.

VERSA IHS was born from the constant request for solutions that could grant – besides than high reliability and safety – a specific attention to environmental sustainability and particularly to the reduction of energy and water consumption.

«Like all the system designed by Aeris Group – concludes Eros Nani – VERSA IHS, unique in the aeraulic scenario of the Textile and non-woven fields, is realized in compliance with the guidelines of the European Directive Erp2018. Energetically speaking, this leads to an exceptional result: the reduction up to 70% of the energy impact for the adiabatic humidification plants as well as the reduction of 60% of the water consumption necessary for the process».

The IHS humidification technology is the heart of the system, with incredible performances: a COPH (Performance Coefficient) higher than 40 and a SEH (Saturation Efficiency rate) of 100%. Available systems on the market usually do not exceed COPH 10 and SEH 50%, meaning that if IHS requires only 1kWh of energy consumption to humidify environments with 100% of processed water, traditional systems require at least 4kWh, four times more, and the double of water consumption to achieve the same result.

IHS’ humidification and cooling capacity is the result of four years of research and it is designed taking care to the strictest hygienic requirements. IHS is the only humidification system in Textile and non-woven in compliance with VDI 6022 standards; this ensures the absence of pathogenic spores, granting at the same time better internal climate, optimal well-being and performances for the complete lifetime of the system.

Efficiency and sustainability

If IHS is the beating heart of the system, the Versadrums filter is the green lung. UNI EN 13779 is a mandatory regulation that has never been taken into proper consideration in the Textile and non-woven aeraulic field. It provides clear guidelines related to the performances requested by all the filtration systems used for cleaning air recirculation.

In conformity to what above mentioned, Versadrums VDF16 is the right answer. It is a modular equipment, made by a set of filtering drums with airflow from inside to outside that keeps the filtration chamber clean. The wide filtration surfaces and the efficient regeneration system allow the installation of filter media with filtration efficiency up to ISO 16890 ePM1 80% (ex F9), with total absence of maintenance up to replacement for normal wear.

VDF can be equipped with fiber pre-separation sections or condensers for heavy particles (SAP) and it is always completed by a ventilating section with automatic stabilization of the operating pressure.

The brain of VERSA IHS is the Digitron 2.0 Vario software; an advanced user interface with an open platform that makes the complete system Industry 4.0 ready.

The software, besides than the thermo-hygrometric control of the process and environments, constantly checks the correct operation of filters and motors, stabilizes the pressures, verifies the correct execution of the given commands with field feedback allowing the continuous supervision of positions, anomalies and consumption and an immediate reply, correction or adjustment of the system.

«Today – concludes Eros Nani – adopting VERSA-IHS as a plant solution in your company means greatly taking care of environmental sustainability: a unique plus that you can spend on the market, considering the growing attention to these issues in textiles and Fashion».

VERSA IHS will be exhibited in a world preview at ITMA 2019; the managers of Mazziniici and AlenA NW will be pleased to illustrate all features and performances with a complete system working.

Info

Where to find Aeris Group at ITMA: Hall 8.01, Stand A204 e A205