Thanks to fifty years’ experience and cooperation with most Textile and Apparel industry manufacturers and top weaving mills in the world, ETV Elettronica Tessile Varese can boast of number of installations in Italy and abroad. Its range of electronic equipment includes two new items: Hygromatic-HMI and Hygrofaster-e, both aiming at Industry 4.0

Established in 1968 by two electronic engineers with a good experience in the Textile Industry, Elettronica Tessile Varese thrives during the Seventies and Eighties, taking advantage of a strategically valuable location: north of Milan, close to Como and Biella, all world-renowned textile manufacturing areas. 2002 is a turning point in its history, not only because of a generational handover taking place, but also because of the move to the current headquarters at Induno Olona. Under a new name, ETV Elettronica Tessile Varese Srl, the company kept making a name for itself as an industrial partner of excellence and began to expand into the international market. Today, 30% of the products goes to the international market where ETV sells directly, while the turnover keeps growing: the remaining 70% of sales goes to Italy, mainly to textile machine manufacturers, with a good percentage going again to countries investing in this industry.

Specialized in monitoring humidity and fabric temperature

ETV is a specialist of hardware and software devices for textile machines (mainly stenter machines, sizing machines, sanfor machines and dryers) to precisely measure residual moisture in fabrics and yarns, as well as on tops and flocks. In 2001, the company also added electronic fabric temperature monitoring equipment; combined with residual moisture monitoring, that plays a basic role in cloth ennobling, mainly for dyeing, printing and finishing processes.

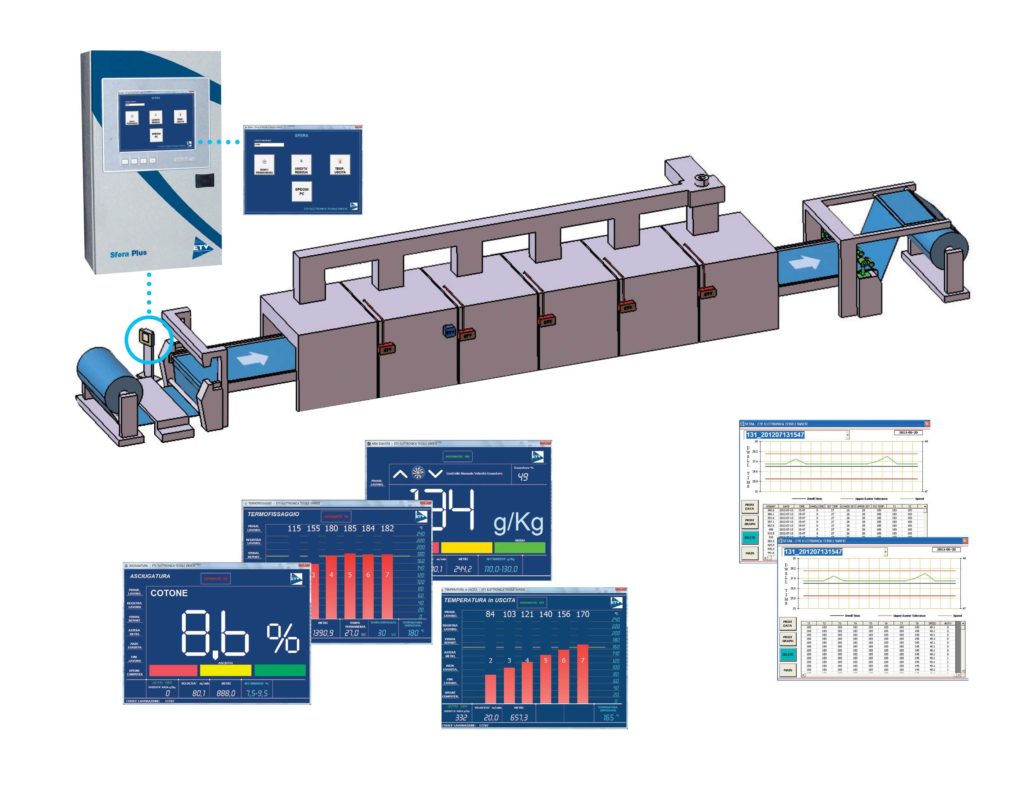

«In the Textile industry – Maurizio Sempio, Managing Director with ETV points out – the stenter machine process, that is the cloth drying and fusing process, rely upon a combination of various parameters (temperature, residence time in the sections, type of material fibres). They are often controlled thanks to a detailed know-how and experience of the operator and to the comparison of results in time. On the contrary, our sensor system integrates the stenter machine, reproducing the cloth temperature along the whole process while enabling an even automatic full adjustment, of the machine. Our system, complete with a Sfera Plus control, operates during both finishing and drying steps: you can constantly monitor the process, and especially optimize it while ensuring a consistent quality of the product. Some other instruments will obtain the same data regarding dryers, tops or flock, reels of yarn or any other textile material you need to know the residual moisture content».

Sfera Plus modular system, equipped with an industrial CPU and a touchscreen display, includes: Hygrobox to monitor residual moisture, Thermocontrol for a contactless monitoring of the fabric temperature and of the dwell time of the fabric in the machine, Hygroair to monitor absolute air humidity and to eject fumes.

New portable instruments

Besides the Sfera Plus modular system, ETV also makes specific systems, e.g. Hygromatic-Plus, now Hygromatic-HMI, CPU and microprocessor device to monitor residual moisture in cloth and in natural as well as synthetic fibres, with automatic machine adjustment. The device covers stenter machines, sanfor machines, sizing machines and dryers in general. The new Hygromatic-HMI version features a restyled case and a 7” touch display; an updated software links to the business network and is remotely controlled, while saved data can be transferred to make it an Industry 4.0 item.

Besides these units, installed on line on textile machines, ETV also developed Hygro Faster EKV, a portable microprocessor instrument to monitor residual moisture for fabrics, yarns, tops or flock, also useful to meter room humidity and temperature; different probes for various applications obtain actual, precise measurements.

At ITMA Barcelona ETV shows a preview of the latest version of Hygrofaster-e featuring a new design and new functions. The case is more user-friendly and includes a colour display. The new menu offers a selection of primary fibres and a submenu with mixed fibres; icons make functions more intuitive; the measuring time is shorter; you can save your measurements; room humidity and temperature are constantly available; a USB port connects other devices, thus making data transfer and management easier. More than that, you can easily recharge your battery like a mobile phone.

Sustainability and industry 4.0 by choice

«Our company – Damiano Albini, Administrative Director points out – does not relinquish its responsibility in terms of environmental sustainability and the rationale of Industry 4.0. Our products let you save energy, reduce emissions and manufacturing wastes, while optimizing the manufacturing process and helping customers be more competitive on the market. At ETV, the concept of sustainability is not just a strap line chosen because most people feel it or simply because it is trendy: it is a clear idea everybody shares. In fact, a sustainable manufacturing process will make our business and its customers grow, create better products at a lower cost».

«With a view to Industry 4.0 – Albini adds – all our products, besides monitoring manufacturing steps and automating some processes, enable a network link for a quicker information management between devices and ensure an even remote monitoring of the production process. All in all, machines will be smarter».

Info

Where to find ETV at ITMA 2019: Hall 1, Booth B109