Cradle to Cradle (C2C) is a set of design principles, which was developed in the 1990s by Prof. Dr. Michael Braungart and William McDonough. C2C describes the safe and potentially infinite circulation of materials and nutrients in cycles. C2C circular economy contrasts with the current business model “Cradle to Grave”, where a huge amount of waste is generated.

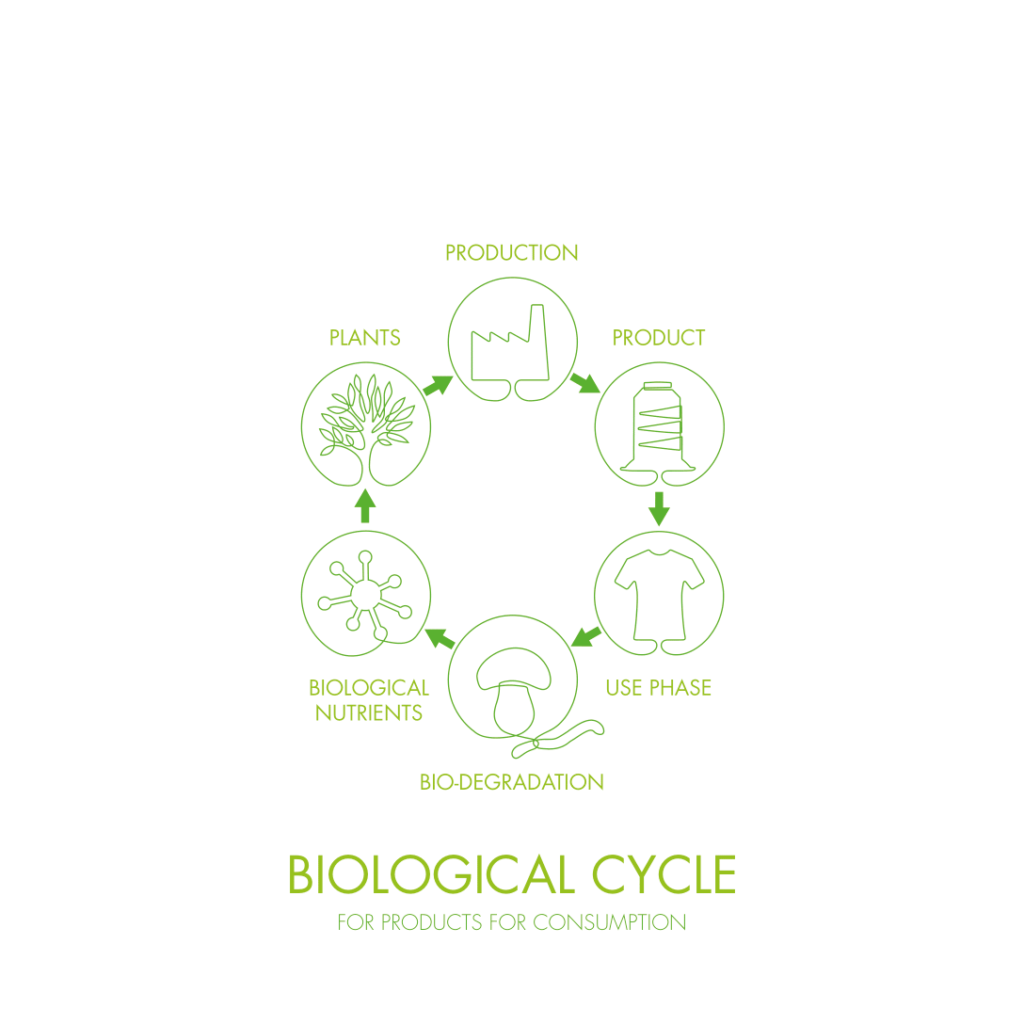

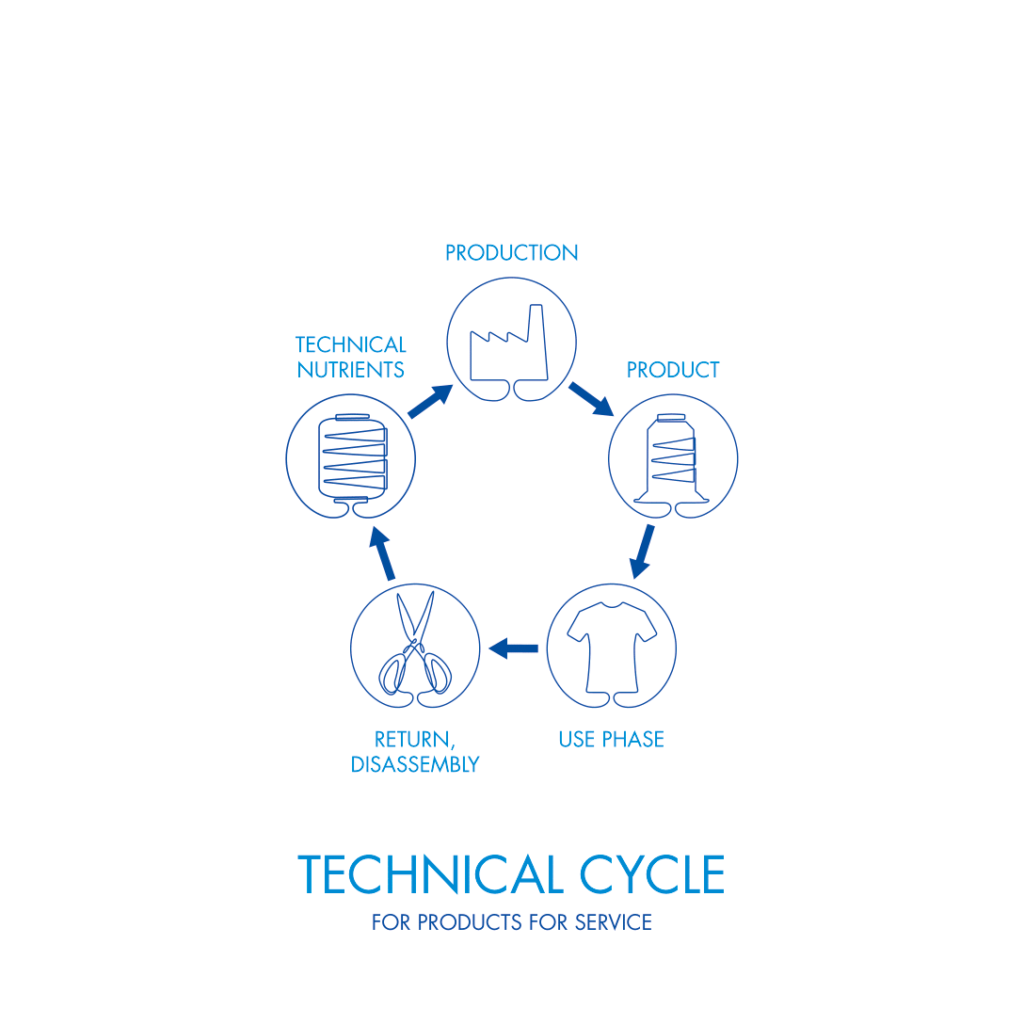

C2C consists of two different cycles:

- textiles circulate in a biological cycle to which they can be returned. After use, they turn into compost or other materials, which are again used to make new products. In this way, old products do not turn into waste but into “nutrients” for a new product;

- textiles circulate in a technical cycle. These products are already optimised during the design and manufacturing process as material resources for their next service life as new products (raw material homogeneity). After use, textiles can be returned to the manufacturer, who reintroduces the material into new products for the technical cycle.

The sewing thread producer Amann Group can offer sewing threads for both cycles with its enhanced Lifecycle range.

Lifecycle Polyamide, a sewing thread made from recycled polyamide 6.6, is specifically developed for the technical cycle. It is made from textile waste and has excellent strength and colour fastness properties.

Now, Amann has completed its range for C2C threads by launching Lifecycle Cotton, the new sewing thread for the biological cycle. Lifecycle Cotton is made from extra-long staple mercerised organic cotton.

Besides the C2C product line, Amann also offers a Recycled product line of sewing threads made from 100% recycled, transparent PET bottles. With this, Amann has taken an important step on the way to reducing resource consumption.