Benefiting from some new partnerships, Morgan Tecnica comes to ITMA with a range that shows the new global approach to the entire apparel manufacturing process. On show: a preview of 3Dress, a new CAD 3D system, a new PLM system and a new entry of the Next 2 cutter generation: Next 2 Δ

Morgan Tecnica, based in Adro (Brescia Province), was established eleven years ago as a specialist of cutting room solutions: from loading and cloth roll handling to automatic spreaders, spreading tables, labelling machines, automatic cutters, plotters and software. Today, for the first time the company looks out of the cutting room to the entire apparel manufacturing process, from design to consumers, with some new specially developed products.

Key word: integration

«Until now we were specialists of some phases of the garment making process» Federica Giachetti, co-owner and President, Morgan Tecnica states. «We then realized that integrated solutions are in great demand, with different systems able to talk to each other; a partner who knows the entire process and can offer an integrated solution is what our customers are looking for. They also appreciate the fact that each module offered has been designed as part of a whole and evolving system» she adds. «With this approach to a global process and with the consciousness that nobody can be an expert of every single area, we decided to go for a strategic alliance with some specialists we selected as partners to fill the gap».

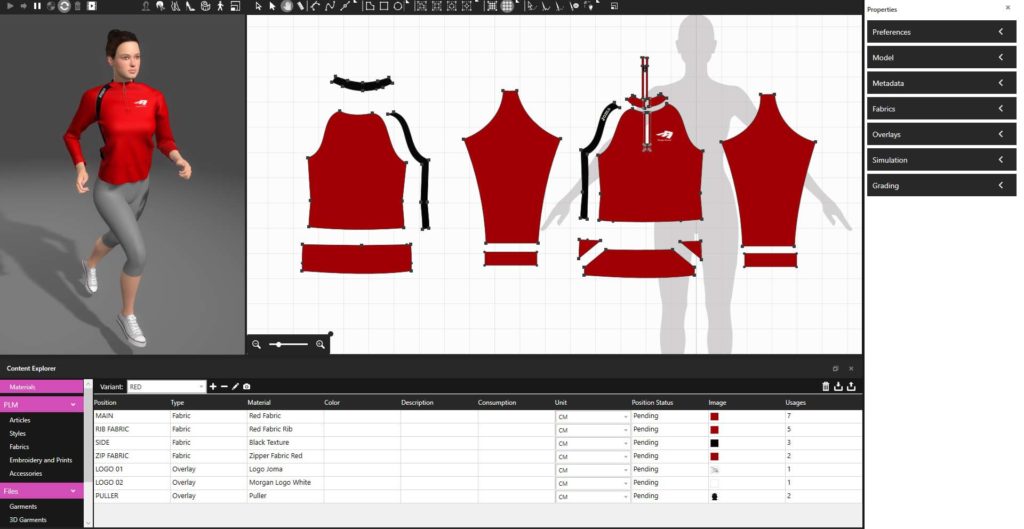

A new 3D CAD

The first partnership was with a company from North America to develop a 3D design software, 3Dress: Morgan Tecnica entered into a world exclusivity agreement of joint development covering the product and its marketing process. «Together we develop the 3D CAD – Federica Giachetti adds – each one with its own know-how: we contribute our knowledge of the clothing industry, they contribute their 3D technology and capacity. Together we obtained a very innovative product: it allows both a real time simulation and rendering, that is a hyper realistic and instant render of the image on the screen. Usually, the rendering process takes several seconds, sometimes even minutes, while ours is available instantly!»

The new PLM software

Again, a world exclusivity agreement with Speed Step, a German company for almost twenty five years on the market in the PLM business. «There is a more and more stringent need of an integrated system to manage every step of the product lifecycle» Giachetti explains. «PLM was not in our range and we could not play by ear with such a complex product; Speed Step is a perfect partner. Our vision is on the same track, their structure goes hand in hand with ours: they are top specialists, however lacking a sales network on the global market to push their product, and we can offer them our distribution network ».

The PLM software is connected with some other historical software developed by Morgan, like Cut Order Planning, which only managed and optimized work orders in the cutting room and now can share information with a PLM software, taking it out of the cutting room. There is also a new release of Analytics, a software to collect and analyze performance and efficiency data from the cutting room. «This system collects data from Morgan spreaders and cutters, hashes them out and forwards them to a server cloud, based on a partnership with an international data service specialist. Data are maintained on the cloud and can be accessed by authorized operators wishing to monitor the performance and efficiency of their cutting room even from a mobile device in real time, anywhere, in a safe way».

Next 2 Δ in a world first

In a world first at ITMA the company also introduces a new version of the Next 2 cutter: Next 2 Δ. It is showed in a 7 cm ply version it is available in a full range of thickness versions.

Top innovation of the system is a new processor – new electronic components – developed with Omron, offering an average 15% higher performance. «The new processor – Mrs. Giachetti adds – offers a quite interesting innovation: algorithms and AI sensors are part of the game and, in case of “dirty” cut files with wrong or inconsistent instructions, they alert the unit. The system reacts autonomously while lowering to almost zero the effects of the mistake and its damage; in fact it does not merely execute the instructions in the cutting room file».

Next 2 Δ features a nicer and user friendlier PC station, with a touch screen and new interactive software pages, as well as an optional very accurate and quickly responding laser safety system. Should the unit detect an obstacle within its outreach, it will slow down without stopping its job. Should the obstacle be within a safety distance, the unit immediately calls stop state. A colour laser band applied under the bridge of the unit shows the progress status: standard, standby, emergency stop.

Innovative piece unloading

Resulting from a partnership with a plastics process technology specialist, the unit is equipped with a game-changing piece unloading system, now available as an add-on on every Morgan multilayer cutter.

«Usually – Federica Giachetti adds – the unloading area next to the cutting window is a PVC or hard plastic carpet; picking up cut pieces is a long and complex job. Our new carpet is a sort of artificial grass carpet, made of soft plastic filaments, not scratching – you can even sink your hands in it without having to “dig in”. It makes this step of the process quick, easy, with no risk for your nails. The system is ready to accept a robotic arm to automatically collect cut pieces!»

Info

Where to find Morgan Tecnica at ITMA 2019: Hall 3, Booth E205