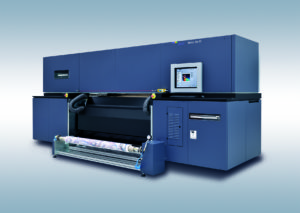

With the new Rhotex 180 TR, Durst presents a new industrial Dye Sublimation system for textile printing that is suitable for polyester and polyester blends, frequently used for sportswear, home textiles and soft-signage. Transfer printing allows for an easier production process compared to direct printing, because the pre- and post treatment is less complex.

With the new Rhotex 180 TR, Durst presents a new industrial Dye Sublimation system for textile printing that is suitable for polyester and polyester blends, frequently used for sportswear, home textiles and soft-signage. Transfer printing allows for an easier production process compared to direct printing, because the pre- and post treatment is less complex.

Calendering makes the ink evaporate from the printed sublimation paper into the fabric where it will compound fully with the material. This indirect printing process produces especially abrasive-resistant and water-resistant results. The Rhotex 180 TR combines Durst’s technological competence from the large format print with textile print and warrants for a reliable 24/7 production. The printer system has a maximum print width of 1850 mm and is equipped with the newly developed Durst QuadroS Printheads. The system has a maximum resolution of 1,200 dpi and a maximum production speed of 200m² per hour.

Durst offers a specially formulated Dye Sublimation Ink System for the Rhotex 180 TR, which is water-based, free of odors, skin-friendly and free of any volatile organic compounds (VOC). The printer system is classified for all current transfer papers and quality levels.