Every single result is then compared with the appropriate Quality Standard; as a matter of fact, the aim is to recognize the standard variations that occur during production.

The standard consists of an average value (which in the case of the title coincides with the nominal one) and two tolerances: the alarm limit and the limit of action. Exceeding the alarm limit indicates the possible presence of abnormalities during the manufacturing process, while exceeding the action limit indicates the certainty of a significant variation in the quality parameters due to mechanical or procedural causes, and it requires a rapid and targeted intervention by technicians.

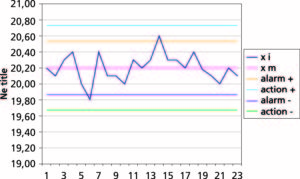

A simple method to represent the daily test results in summary form is the Control Card; it consists of a horizontal line (abscissa) that represents the time and a vertical line (ordinate) divided in units in which the value of proof is expressed (e.g. title, irregularities, resistance etc.)

From the vertical line, 5 horizontal lines start which identify the average standard, 2 alarm limits, lower and higher, and 2 action limits, lower and higher.

With the help of the Control Card it is very easy to visually identify any deviation and exceed of limits (out of standard).

The chart in table 3 shows an example of Control Card related to the title control on a Ne 20 yarn.