As its impressive premier, Stäubli lately presented the production of African damask at high speed on a type SX Jacquard machine equipped with a specific harness with 12,696 cords in conjunction with an air-jet weaving machine operating at a rate of approximately 950 weft insertions per minute. The new LXL Jacquard machine with 11,682 hooks and Stäubli harness is particularly suitable for large-format applications. LX Jacquard machine with a Stäubli harness producing fantasy ladywear with remarkable designs was also on show at Itma.

As its impressive premier, Stäubli lately presented the production of African damask at high speed on a type SX Jacquard machine equipped with a specific harness with 12,696 cords in conjunction with an air-jet weaving machine operating at a rate of approximately 950 weft insertions per minute. The new LXL Jacquard machine with 11,682 hooks and Stäubli harness is particularly suitable for large-format applications. LX Jacquard machine with a Stäubli harness producing fantasy ladywear with remarkable designs was also on show at Itma.

The new LX12 Jacquard machine for weaving narrow fabrics such as ribbons and labels were shown at Itma with 192 hooks and harness with 8 repeats. The Univalette Jacquard machine was also in operation. Stäubli also presented the third generation of its rotary dobbies, the S3060/3260 series, that reaches new heights of performance and reliability.

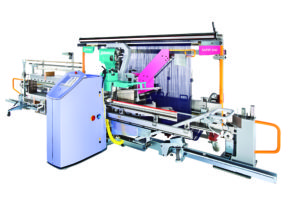

For the weaving preparation systems business unit Staubli is launching the Safir S60, being demonstrated in Milan drawing in a four-colour 175cm-wide warp with Nm 135/2 and Nm 170/2 cotton yarns without a lease, and the mobile SAFIR S40 drawing-in machine. The warp-tying process was demonstrated with two warp-tying machines: Magma for technical and coarser yarn counts and the proven Topmatic for standard applications, handling even the finest yarns.

The TF weaving system is a complete weaving system with a maximum of modularity, ideally allowing individual configuration. The TF system, developed and produced by Stäubli, is designed to fulfil specific needs of future-oriented weavers of new fabric types such as heavy multilayers, multilayers with new types of structure and material mix, reinforcing fabrics for lightweight applications and spacer fabrics.