Research never ends at Morgan’s nor does a continuous improvement, from HR to products. We analysed their achievements with Mr. Nicola Messali, since last October sales manager, Morgan Tecnica. In the wake of a smooth, steady growth that marked the development of Morgan Tecnica, based in Adro (BS), from the very start, the teams in each section gradually introduced new professional profiles with specialists able to share the company’s target with enthusiasm, as is the case, for example, of Mr. Nicola Messali, sales manager since October 2015.

A Stronger Management

After 15 years’ experience on the textile/clothing retail market, Mr. Messali now supports the owners Federica, Fabrizio and Franco Giachetti, President, CEO and general manager respectively, in developing their business strategy and sales targets, as well as in taking charge of domestic and international markets. “For several years, as sales manager I have been engaged in apparel retail with different companies, Nicola Messali states, and also managed some start up to build sales and product distribution networks with excellent results. I started with Morgan in October 2015 exploiting my knowledge and trying to blend it with a new subject more upstream in the textile/clothing supply chain, however with a common language, similar issues, similar markets and players”. “At present, in my opinion, a deeper knowledge of products and reference markets is of essence – Messali adds – from Italy to America, from India to Bangladesh, from Vietnam to Cambodia, Indonesia… where trade shows are available and where one can meet dealers and clients as well. A demanding task at the moment, however, there are two things I mainly believe in: daily hard work and a great attention at what customers need”.

New Products Come along

In such a dynamic business, new products are also on offer. After the most recent launch of Visual Nest (see the description on foot), around June Morgan Dynamics, the company’s software house, will launch a new 3D collection design software, conceived to cut time and costs through an innovative prototyping method. We are also developing a new generation of cutting room management software and of machine management software; a technical and operational restyling will result in the launch of new systems. “Today, the most advanced changes in machines originate from a development of mechanics,  electronics and software – Messali points out. We know quite well that all that future technology can do will improve a machine’s potential in terms of performance, efficiency, lower consumption and user-friendly devices. R&D is the DNA, the driving, hyperactive force of Morgan Tecnica; it has always been the top priority as far as both mechanics (design department) and software (Morgan Dynamics) are concerned. The quick growth of the company, year after year, is a strong evidence of the fact of being aware that for them to be a major port of call on the market, they have to be future oriented and look at the next machine generation to come”.

electronics and software – Messali points out. We know quite well that all that future technology can do will improve a machine’s potential in terms of performance, efficiency, lower consumption and user-friendly devices. R&D is the DNA, the driving, hyperactive force of Morgan Tecnica; it has always been the top priority as far as both mechanics (design department) and software (Morgan Dynamics) are concerned. The quick growth of the company, year after year, is a strong evidence of the fact of being aware that for them to be a major port of call on the market, they have to be future oriented and look at the next machine generation to come”.

The New Visual Nest

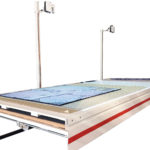

“Visual Nest – Mr. Messali adds – is a product originated from demands developed at Morgan Tecnica’s to meet the need to intuitively and immediately control and nest striped and checked fabrics on a marker before cutting”. Let us consider it more closely. Visual Nest is a convenient, effective system to view and modify markers in real time, on the spreading table. The system is conceived to help the spreading by hand of striped or checked fabric on a needle table, through a grid of theoretical repetition ratios duly projected. A useful tool and a guide to align and hold the cloth, it proved of further applications both for spreading patterned fabrics or prints by hand, and for machine spreading of plain fabrics, to check flaws, to manage overlaps, to check the compliance with minimum width and length of a layer during the spreading operation, ecc. In fact, the system displays both the theoretical repeat lines and the entire marker, with every template highlighting any tracking points, thus enabling the operator to directly act on the layer by means of his mouse to drag or rotate every single shape as the underlying fabric requires, finally saving them in a new file for the cutting.

Basic Features

Some important technical and operational features of Visual Nest are:

- a 3.5 x 2 meter projection area for each projector; the possibility of a concurrent management of several projectors;

- the possibility of changing the repetition pace and of moving single lines in case of broken pace;

- the possibility of changing the repetition angle to support off grain fabrics and of moving single items within the marker to ensure a suitable matching. Again… the possibility of rotating single items of a marker to support off grain fabrics and of customizing a combination of shades to adapt it to any kind of fabric.

The standard ISO format makes Visual Nest compatible with any existing installations of spreading and cutting units and with any CAD/CAM systems.

The standard ISO format makes Visual Nest compatible with any existing installations of spreading and cutting units and with any CAD/CAM systems.