Its name is Wiln-Tex, a small company with registered office in Milan, based in the Bergamo province, with a history of recent success. However, its structure is the only recent part of it; in fact, a few years ago the leading team, which contributes an almost thirty years’ experience in the European textile machines industry, rushed into a risky professional adventure.

FASHION COMES FIRST…

The adventure started about ten years ago with bespoke promotional garments. Then, two years ago, exploiting their knowledge of the textile industry, they added a looms and jacquard machines import business from China; hence Wiln-Tex was split in two divisions: Fashion and Textile Machinery.

Tailored branding apparel is 100% made in Europe; we conceive the range and set of samples of the client starting from a graphic project including fabric variants and product research; sportswear set of samples are made with technical materials and accessories in mind; we work in close cooperation with our clients to implement branding projects, develop bespoke garments, accessories, gadgets. We also make apparel and accessories for sports events of ski and winter sports, sailing, water sports, ensuring a top customization even for smaller lots: from Egyptian cotton jacquard towel to 100% silk ties from Como, from 100% gauzed cotton fleece sweatshirts to piquet polo shirts, to approved ski helmets, etc…

…FOLLOWED BY TEXTILE MACHINERY

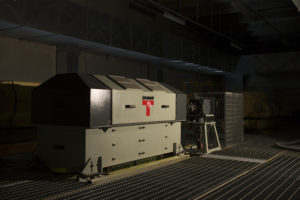

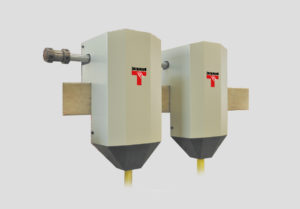

Therefore, the textile machines import business from China started a couple of years ago, mainly towards the European market. Assuming that Chinese manufacturers made great strides towards a certain performance and quality standard, though still very far from Italian and European companies, we thought we could import machines from China, adjusting them to obtain a CE conformity certification and to meet technical and electronic requirements so as to “ennoble” them by adding European technology, certainly not to be compared with Chinese technology. Wiln-Tex leading team covers all commercial aspects; a distribution network has been developed; rather than a single agent to cover a country – as it is the case on the international market – in Italy we provided for an agent in each textile cluster, like e.g. in Biella, Como, the Brianza region, Prato, etc. Beside the sales network, local engineers quickly supply the necessary service, spare parts and updated technical details.

Therefore, the textile machines import business from China started a couple of years ago, mainly towards the European market. Assuming that Chinese manufacturers made great strides towards a certain performance and quality standard, though still very far from Italian and European companies, we thought we could import machines from China, adjusting them to obtain a CE conformity certification and to meet technical and electronic requirements so as to “ennoble” them by adding European technology, certainly not to be compared with Chinese technology. Wiln-Tex leading team covers all commercial aspects; a distribution network has been developed; rather than a single agent to cover a country – as it is the case on the international market – in Italy we provided for an agent in each textile cluster, like e.g. in Biella, Como, the Brianza region, Prato, etc. Beside the sales network, local engineers quickly supply the necessary service, spare parts and updated technical details.

The ranking of Wizard looms and Tiger jacquard weaving machines on the market is quite specific. They do not claim to compete with big European manufacturers, their target being different. The company aims at smaller weaving mills or subcontractors, wishing to install convenient yet versatile and operational systems, probably considering Wiln-Tex machines as a valuable alternative to second-hand units, at a similar price, though offering a warranty, customer service and updated technical details.

BETWEEN PRESENT AND FUTURE

For the time being the company’s major markets are Turkey, Northern and Southern Korea, Iran, India, Spain, Portugal and, though marginally, Italy, a rather difficult and demanding market.

Wiln-Tex’s key target is a steady attention to machines in order to be able to improve them as much as possible with the help of experts and engineers, so as to gain an easy access to more selective market, not only in terms of price but of performance as well.