To ensure weavers’ security for both fabric quality and profit margins, the Uster Q-Bar 2 formation monitoring system is the ideal solution.

Operators should be everywhere at the same time – checking, fixing, keeping the machines continuously running – no matter in which weaving mill, all around the globe; Q-Bar 2 helps working as an extra operator dedicated to a single weaving machine.

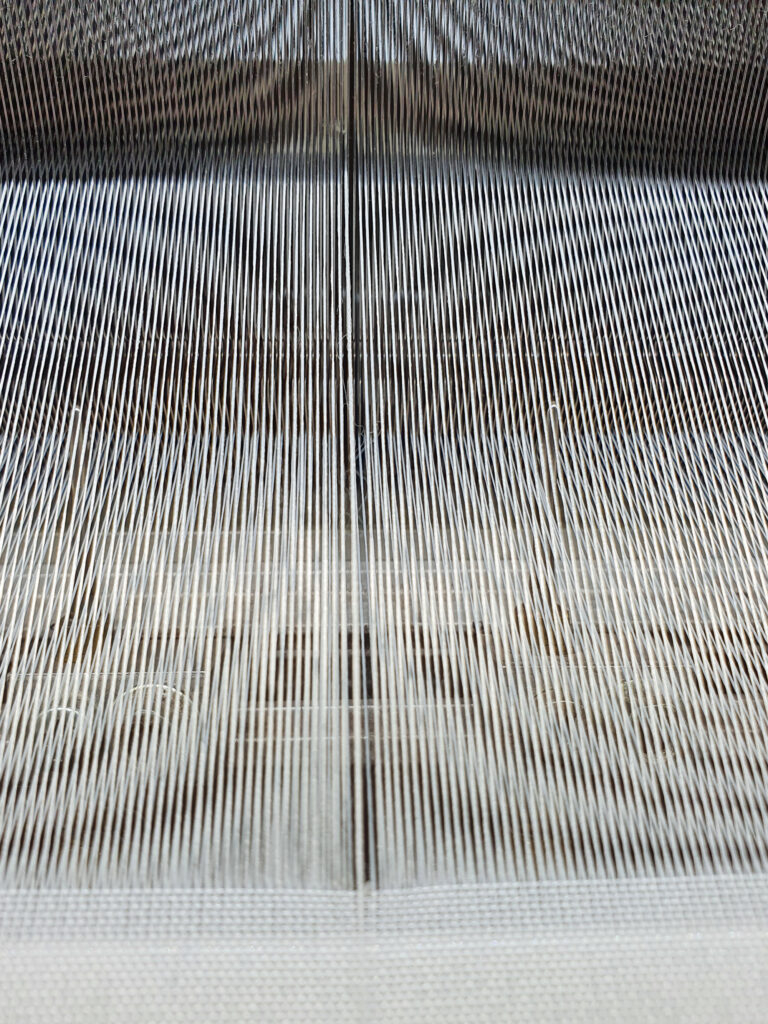

It has its inspection position within the fabric formation area, allowing it to respond quickly when a defect appears and avoid long-running or repeating faults. Alarms and stop signals alert the operator to correct problems immediately; this early detection reduces second quality and material loss.

Q-Bar 2 also monitors critical machine units in the formation zone with automatic, in-line inspection. If there is a problem here, the system makes it easy to identify and eliminate it, preventing further defects, and again maximizing fabric yield.

Don’t risk profitability

A worn-out part might be overlooked, setting off a drama affecting margins. Defects could be repeated, showing up again and again – linear meter by linear meter – for as long as it takes to identify the fault and fix the issue.

Long-running defects can also arise from dirty parts, or from missing or inadequate maintenance. Whatever the issue, what they have in common is that they spoil lots of good fabric – worst of all in the middle of the web.

Q-Bar 2 is able to automatically detect these problems and avoid damage: the solution works with various weaving machine types (except water-jet and jacquard).

Weaving defects can have various root causes, so Uster Q-Bar 2 provides different algorithms to identify specific defects and their causes. With this knowledge, it is possible to prevent defects during the actual weaving process.