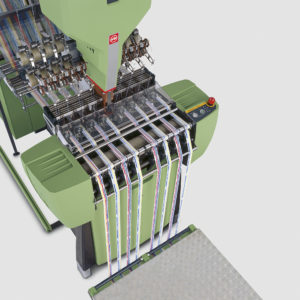

Jakob Müller AG introduces three innovative machines. The NH2 53 electronically controlled narrow fabric loom (in the picture), with a new type of main drive and a shedding device that moves the shafts non-mechanically. Drive is provided by an LRK torque motor, which powers the loom directly without intermediate gearings or belts. The heald shafts are driven by linear motors, which facilitates unlimited repeat lengths. Mechanical components such as cam discs or patterning chains are no longer required for shaft control and this greatly reduces the machine’s energy requirement.

Jakob Müller AG introduces three innovative machines. The NH2 53 electronically controlled narrow fabric loom (in the picture), with a new type of main drive and a shedding device that moves the shafts non-mechanically. Drive is provided by an LRK torque motor, which powers the loom directly without intermediate gearings or belts. The heald shafts are driven by linear motors, which facilitates unlimited repeat lengths. Mechanical components such as cam discs or patterning chains are no longer required for shaft control and this greatly reduces the machine’s energy requirement.

UV40-G220/H automatic, cutting-to-length machine, used for the automatic cutting of light to medium-weight belts, as well as elastic and non-elastic tapes. The cutting lengths are freely programmable up to 1,000mm. A hot cutting device is available for narrow fabrics made from synthetic yarns, which allows the simultaneous sealing of the cut edges. A sensor ensures cutting that precisely matches repeat without waste. The process speed amounts to 15 pieces/min (at a length of 200mm). The UV40-G220/H can be individually adjusted for various applications.

The DNB-EL-32 electronically controlled, right-right warp crochet knitting machine, produced by COMEZ International. It has a working width of 82cm and permits the manufacture of spacer knits with pile heights of 1-20mm. The machine is available for yarn counts of 5, 10, 12, 15, 18 and 20 E and its range of applications extends from spacer knits to tubular medical textiles and high-performance tapes in special fibres for the automotive and construction sectors.