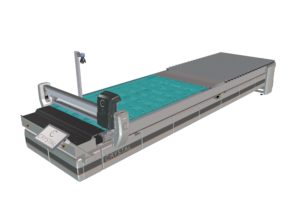

Innovative Crystal project by bierrebi Italia keeps on growing as high quality landmark for single ply cutting for fashion, automotive and furniture. Its sophisticated features and its cutting accuracy allow to substantially reducing all the management costs at a very low level. Crystal continuous development completely carried out internally at bierrebi Italia has been reaching the expected further goals:

Innovative Crystal project by bierrebi Italia keeps on growing as high quality landmark for single ply cutting for fashion, automotive and furniture. Its sophisticated features and its cutting accuracy allow to substantially reducing all the management costs at a very low level. Crystal continuous development completely carried out internally at bierrebi Italia has been reaching the expected further goals:

- Slide away: automatic unloading system to increase prototype productivity. Thanks to the long time bierrebi experience on fully automated cutting machinery, crystal acquired the special system to move and unload the cut pieces. In a few seconds, it is possible to start again the cutting process while the operator collects the material just cut.

- Vision: images management and pattern matching placements (stripes and checks). HW and SF application, which can automatically place and cut extremely quickly. Once fabric is on the cutting area, a high-resolution camera will get the fabric mapping and a latest generation software will create the best placement. Then it will be immediately converted in a file and cut will be carried out.

Thanks to its peculiarity, Crystal is getting a great market liking, not only in Italy but abroad too. Some important wholesale agreements have finalized such as a deal with company Ozbilim Ltd in Turkey which presented Crystal during Clothing Machinery 2016 Show, last April in Istanbul.