At ITMA 2019 Air International will unveil Xiros, a new air treatment unit: compact, reliable, high-rate, it features a water injection technology with a Venturi type air expansion absorption depending on the fluid’s features

High-rate humidification, monitored water consumption, brushless technology, reversed air or outside air cycle: these are some benefits of Xiros, the latest highlight by Air International to be shown ad ITMA 2019. At the most important trade show in the textile industry, scheduled to take place in Barcelona from 20th through 26th June, the company based in Fara Gera d’Adda (Bergamo province) acknowledges its long experience in the design of air treatment systems, with “turnkey projects” for new installations, changes and revamping of existing plants, as well as customized solutions to monitor humid climate conditions, technologic air and process air.

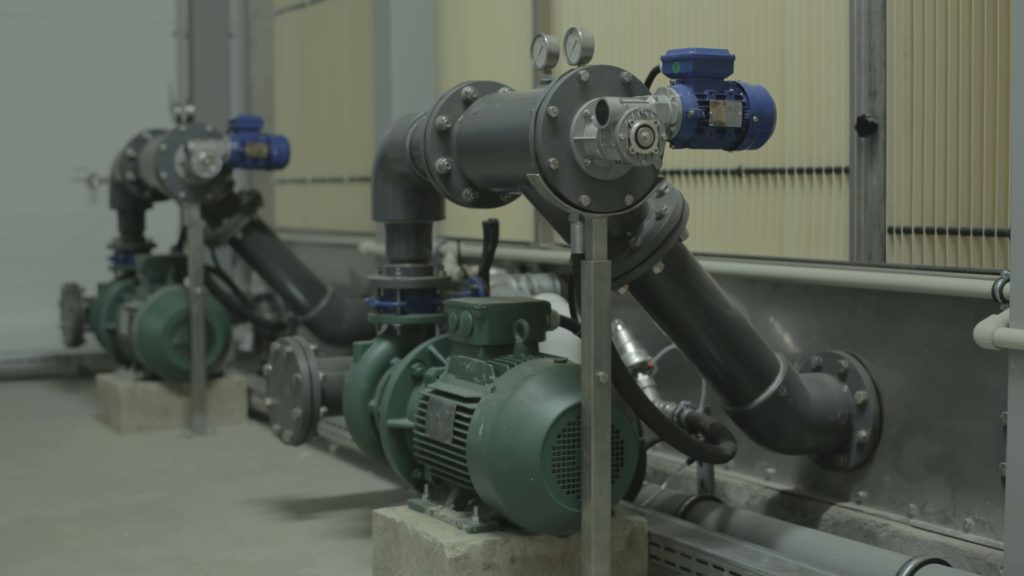

«Xiros controlled humidification air treatment unit offers a high-rate humidification due to a water injection technology with a Venturi type air expansion absorption, Air International CEO Gianluigi Piccini explains. «Combined with a continuous monitoring of thermal hygrometric conditions of fluids pushed by high-rate and low noise fans, this technology produces major results in a compact, reliable unit. Air sucked into brushless axial fans is scanned by temperature and humidity probes and pushed into the Venturi humidification section, where the quantity of injected water is automatically monitored according to the features of the fluid».

High efficiency is ensured

Featuring a stainless steel induction system, easy to open for maintenance and sanitation measures, Xiros was designed focusing on energy saving and an ensured efficiency. Once treated, the fluid is scanned to check the expected result. «The unit is flexible; one can adjust the flow rate while saving energy wherever the process does not need it» Piccini adds. «The machine comes with an electronic control unit, including a microprocessor to calibrate the different parameters. The induction system with gauged, engineered holes, comparable with a turbulent motion in all respects, exploits the lamination of a confined flow; at a stated speed the flow produces depressions that activate the mixing of inlet air with ambient air on short, however continuous paths, hence making the system highly efficient. The confined flow comes out at high speed as a shrunk flow due to higher speed at the centre of the nozzle as against its edges: the resulting depression makes the neighbouring ambient air flow back mixing it in the resulting jet».

Technology and innovation

Technology and innovation are the core of Xiros as well as the path to the growth of Air International; a renewed corporate structure is based on managers, workers and professionals who bring their twenty year experience in past companies and a comprehensive knowledge of industrial air treatment as well. «Human resources and their professional development are our brand pillars» Piccini adds. «We share our targets, ideas and projects and engage ourselves to carry out them together; this approach gave us the opportunity to update our know-how with innovations to meet the market demand and to reach the evaporative cooling and the non-woven sectors, just to mention a few. We are also investing more in these fields. We enlarged our agent teams in Italy to strengthen our presence on the textile market, offering high energy saving and low environmental impact systems ».

– Controlled water consumption

– Variable capacity

– Brushless technology

– Reversed air or outside air cycle operation

– Full control of thermo-hygrometric conditions

– Easy maintenance and sanitation

Air engineering is part of our DNA

The fight against wastage while maximising efficiency is a common thread running through the solutions Air International offers, with specific research and energy consumption checks in order to ensure top savings and the lowest possible environment impact. The engineering stage is basic, from design to risk assessment, to the selection of materials. The company recently offered its expertise and capacity to support big projects where on time delivery and the capacity to manage unexpected circumstances are fundamental. Every solution is a “turnkey project” based on our engineering service and a good organisation.

Service is an added value

Finally, after sale service is a show-piece of the Bergamo area company. Besides a good training of the staff to carry out a routine maintenance – even on systems of different brands – Air International offers captive parts. «Every new installation receives a full list of suggested spare parts and consumption material for a correct operation» Piccini states. «We also ensure a constant monitoring of our products, thanks to a 24h service system. Trouble reports reach us in real time and we can respond with a solution very quickly. We also offer regular checks of correct function of every equipment with a report and suggestions to improve the system efficiency».

Info

Where to find Air International at ITMA 2019: Hall 8.1, Booth A211