For years now, Sustainability has been a constant in 3M’s work. The company utilizes scientific tools to develop recycling-based solutions, realizing comfortable, innovative and environmentally friendly Fashion items

In today’s modern landscape, being profitable is no longer the only measure of what makes a “good” company. Sustainability has become a major focal point for industries and titans looking to re-tool their orientation, but for 3M, Sustainability has been embedded into the company for decades. 3M’s Pollution Prevention Pays (3P) program was initiated back in 1975, and the company’s Sustainability efforts have been recognized by inclusion on the Dow Jones Sustainability Index for nineteen consecutive years.

Founded in 1902, the Minnesota-based, the multinational company has been developing a range of products and services to change the conversation about how to solve real-world problems, bringing a sizable number to market each year. Whether it be that of individuals, groups at large, or industries as a whole, with operations in more than 70 countries and over 90,000 employees, it’s become one of the loudest voices in an ever-evolving dialogue.

Increasing demand for “ethical” purchasing and production

The Fashion industry is the world’s second largest polluter, landing the penultimate title right behind the oil industry. Over 80 billion pieces of clothing are consumed every year, with 32 million Olympic swimming pools worth of water wasted in the process of production, as was uncovered by the journalistic team working on the documentary film “The True Cost”. With two thirds of fibers coming from cotton, the amount of water that goes into its growth alone puts a tremendous strain on the environment, and is one of the reasons why renewable materials are becoming increasingly important for those looking to have a positive impact on the planet. Increasing awareness with regards to these issues has created a demand for “ethical” purchasing and production, primarily in the Fashion industry, and consumers and companies are looking for alternative solutions to the previously established predominant model.

Insulation with post-consumer recycled materials

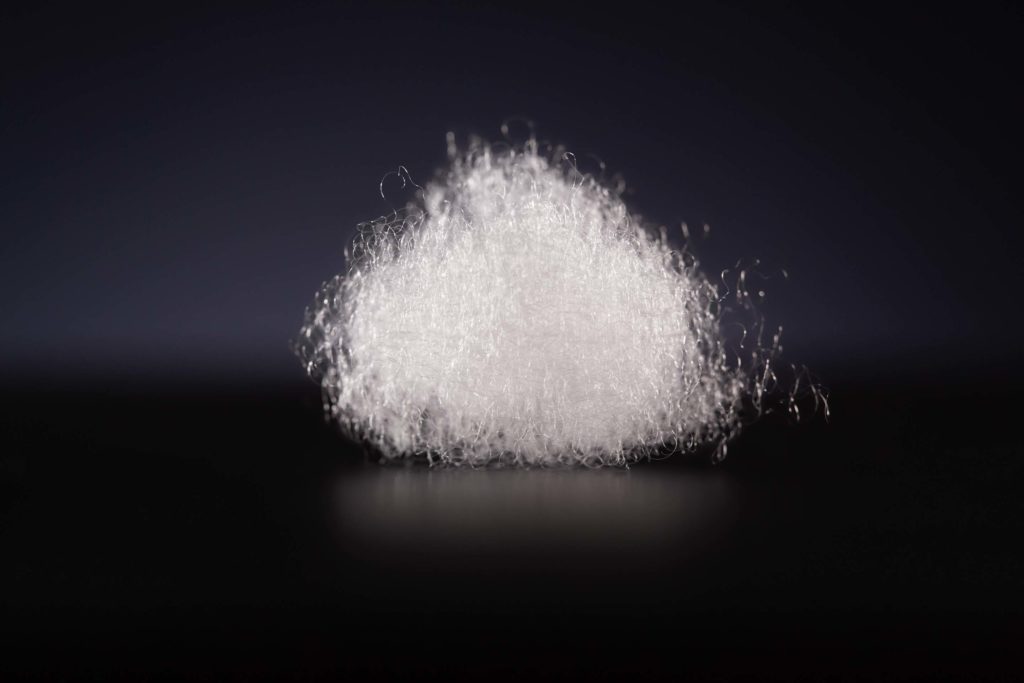

But not all companies are new to this task. With tremendous changes facing the global market, 3M has been working to develop products and solutions to big-picture problems for years now, utilizing scientific tools to make the world a better place through products like 3M™ Thinsulate™ Insulation. The term “circular economy” is an important concept for manufacturers, creating opportunities for reducing waste by reusing, and repurposing pre-existing materials in innovative ways. Made up of post-consumer recycled materials, 3M™ Thinsulate™ Recycled Insulation has become one of the newest responsible materials on the market. The product is used in the production of outerwear jackets, helping keep warmth in and bulk out of the picture.

First successes

They started by revolutionizing the skiwear industry, creating a material that was less bulky but just as warm, enabling athletes to increase their speed and comfort through intelligent, practical design. The unique microfiber constructions of 3M™ Thinsulate™ Insulation were much smaller than the fibers of other synthetic insulations, which helped make them more effective at trapping insulating air. The more fibers per square inch, the better an insulation performed in retaining the body’s radiant heat. But over the many years it’s been in use, 2018 saw substantial developments to its make up and function, creating ample opportunities for further market integration.

Green technologies

Reducing their carbon footprint, 3M is now making materials with 83% post-consumer recycled material and has developed an entire facility dedicated to converting process-related waste into high quality plastics.

With three new recycled content products, the 78% Recycled insulation is designed to reduce waste at an affordable cost, while the 83% Recycled insulation is one of the premium products in the portfolio. The technology creates options for retailers and clothing designers to opt into sustainable measures, without having to forego quality or raise prices in a way that would be detrimental to their positioning.

Repacing natural down lining

Perhaps one of the more exciting products is the 3M™ Thinsulate™ 75% Recycled Featherless Insulation, which has the capacity to replace natural down lining. It offers extreme warmth for extreme conditions, expanding the range and the durability of recycled outerwear materials with its fibers made from recycled polyester.

This new model provides versatile design capabilities for a range of styles, and is highly compressible for travelers and limited space. Its water resistant fibers and breathable nature help to retain body heat and keep you comfortable, whether you’re braving the blustery streets of a Boston winter or out trekking in the Nepali mountains.

Certified innovation

All three of these new products have received industry certifications, ensuring that they’re up to snuff for whatever adventure, or daily task, awaits those in need of durable outerwear products – and all in the name of mother nature. Besides receiving certification to the Global Recycled Standard (GRS) verifying their recycled content, they meet the harmful substances requirements of Standard 100 by OEKO-TEX® and have been awarded the OEKO-TEX® Certificate for Product Class 1 by Hohenstein Institutes (meets the human-ecological requirements of the standard presently established for baby articles). They also are bluesign® approved which means they meet the strict safety and environmental criteria of the bluesign® system (these products are made from bluesign® approved chemical products and raw materials and are produced in a resource conserving way with a minimum impact on people and the environment)

Future prospects

Creating opportunities and incentives for product designers to integrate the circular economy into their business model opens up possibilities for manufacturers to make better, smarter choices, and the outerwear industry has been eager to adopt them for some time now. At the heart of the matter, the outerwear and exploration manufacturers are built around better understanding and connecting with the world around us. With companies like 3M creating the resources for customers and creators to financially commit to practices that align with their values, the rest of us can breathe a little easier knowing that making the world a cleaner and safer place is on the radar of an entire industry’s network, bringing us one step closer to a sustainable, circular economy and a less harmful future for the Fashion industry.