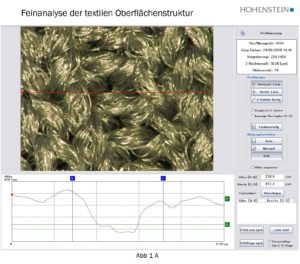

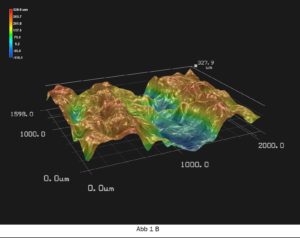

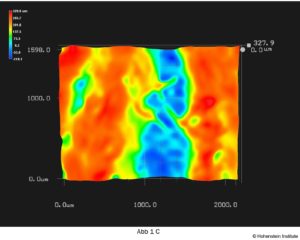

Digital analytical process leads to development of friction-optimised textiles worn next to the skin. Researchers at the Hohenstein Institute have established a digital method for three-dimensional analysis of the surface of textiles that come into direct contact with people’s skin. By using the new microscopy technique, the scientists are now able to describe the mechanical nature of the contact between textile surfaces and skin in far greater detail. They use a new process called 3D profilometry to analyse the interaction between flexible materials such as textile and skin. The process will mainly help the industry to improve the friction properties of textiles that are normally in direct contact with the skin. The Life Science researchers at the Hohenstein Institute use a state-of-the-art 3D digital microscope to carry out their topographical analysis. Firstly, this allows the structure of the textile surface to be analysed in great detail, from the macro- to the micro-texture (see Figure 1). Secondly, it also makes it possible to predict where and how a fabric will contact and rub against human skin, especially when the textile is pressed vertically down on to the surface of the skin. It can therefore be predicted exactly which textile structures (fibres/yarns) will touch the skin as contact increases, and what proportion of them will do so. This 3D surface analysis of textiles can usefully be applied to all textiles worn next to the skin, which exert considerable and lasting mechanical strain on the wearer’s skin during normal use, for example when exercising, or when protective clothing, orthoses, prostheses or support stockings are being worn. Studies show that there is a growing demand for new surface-optimised textiles of this kind, because an increasing number of people suffer from over-sensitive skin conditions (e.g. inflammation, wounds, pressure ulcers ecc.). The method can also be used to gain a better understanding of capillary effects in textiles, e.g. the way fluid and odour spread during sweating.

the whole textile, including all structural

elements (fibres/yarns). The method has

been developed as part of a Cornettetra

project by the European research

consortium “Touché” – “Boosting

innovation through application of a basic

understanding of the process and testing

of textile touch and fabric feel”.

Digital conversion of the percentage of the

textile in contact with the skin, based on the

height profile. © Hohenstein Institute