Outlast Technologies LLC and the renowned fiber manufacturer Thai Acrylic Fibre Co. Ltd., Bangkok/Thailand, announce they have succeeded in developing a new generation of a PCM acrylic fiber with Outlast® technology. This new fiber provides four times the performance and offers perfect climate comfort for apparel and home textiles.

Outlast Technologies LLC and the renowned fiber manufacturer Thai Acrylic Fibre Co. Ltd., Bangkok/Thailand, announce they have succeeded in developing a new generation of a PCM acrylic fiber with Outlast® technology. This new fiber provides four times the performance and offers perfect climate comfort for apparel and home textiles.

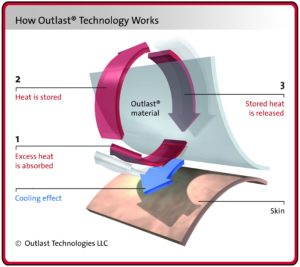

A new production process has allowed the Outlast® acrylic fiber to perform four times better than the existing version. «We are using now a non-encapsulated pPCM system and we no longer work with encapsulated mPCMs here», says Martin Bentz, President of Outlast Technologies LLC, Golden/USA. «This change allowed us to improve the performance of the new Outlast® acrylic fibers enormously. With that, the spinning and dyeing properties are enhanced». This especially plays a positive role for dark colors – darker tones are easier to achieve now through a better color absorbance. The new Outlast® acrylic fiber blends very well with wool. It is well suited for use in socks, knitwear (e.g. pullovers) and home textiles (blankets) offering the significant added value of a dynamic heat and moisture management. The new Outlast® acrylic fibers absorb excess body heat, store and release it. The performance fibers regulate the climate proactively – in contrast with other technologies that only wick away humidity. Outlast® technology proactively manages heat while controlling the production of moisture before it begins, so less humidity is produced inside the apparel. This Outlast® difference also results in more comfort as well as improved hygiene, which is important especially when it comes to socks.